Refinery Inspection

Integrity NDT supply comprehensive Asset Management Services to support our Refinery and Chemical Plant clients. Working closely with our client engineering teams to support their inspection needs with an innovative approach to providing inspection solutions. We have the plant inspection experience and offer an inspection management ‘package’ approach, providing support from planning through to the management of the final inspection results.

Integrity NDT supply comprehensive Asset Management Services to support our Refinery and Chemical Plant clients. Working closely with our client engineering teams to support their inspection needs with an innovative approach to providing inspection solutions. We have the plant inspection experience and offer an inspection management ‘package’ approach, providing support from planning through to the management of the final inspection results.

. …working in accordance with our own suite of inspection procedures and techniques, we ensure that the correct techniques and procedures are applied, by appropriately qualified and experienced operators…

Our philosophy is to ensure that the work is carried out “right first time” rather than have inaccurate data or embark on a programme of rectification.

The team will work alongside our client engineering departments coordinating key interfaces on site and with our valued experience provide a professional plant NDT Support Service. We ensure that all work is carried out and reported efficiently and in compliance with the requirements of the relevant standards and codes.

From Pre-Shutdown Planning Stages, through to the provision of Professional Inspection and Summary reports at close-out, Integrity NDT work with our client partners to ensure that Shutdown NDT is not only cost effective and efficient but also makes a significant contribution to Plant Integrity and Asset Management.

From our extensive experience of the fabrication and in-service inspections of heavy wall pressure vessels such as Reactors, Drums, Heaters etc, Integrity NDT have formulated a proven approach to the selection of inspection applications, specific to the detection of both fabrication and in-service defect flaws, maximising defect detection and accuracy of defect sizing

From our extensive experience of the fabrication and in-service inspections of heavy wall pressure vessels such as Reactors, Drums, Heaters etc, Integrity NDT have formulated a proven approach to the selection of inspection applications, specific to the detection of both fabrication and in-service defect flaws, maximising defect detection and accuracy of defect sizing

Hydrogen damage and related HTHA defect mechanisms are always of concern and a focus to Refinery Plant Engineers and Managers. Integrity NDT have significant experience in this area and specifically regarding the early detection of hydrogen damage.

Our Focus

…Our services are based on understanding, defining and preventing risk

Main inspection methods are:

- TOFD inspection

- Phased Array UT

- Manual Ultrasonic inspection

- Ultrasonic Back Scatter Technique

- Ultrasonic Velocity Ratio Measurement

- Spectrum Analysis

- Metallurgical Investigation (Replication)

- Detailed information about inspection techniques are given in NDT Services Section.

Software Systems

…it is the use of our in-house developed task specific software systems which significantly adds value to our Asset Management approach to Project Management from outset to delivery.

We provide Shutdown Management Software

- Shutdown ‘turnaround’ inspection management. We utilise ‘QUARTSITE’, our project management software, to which we upload the planned work scope. The project software is designed specifically to manage inspection activities, controlling and storing the related information and documentation typically generated during large shutdown project works, Inspection Report generation/task status tracking.

We provide surface preparation operatives

- Pre-inspection surface preparation. By managing the surface preparation activities directly, we ensure adequate and cost-effective surface preparation is achieved, essential to main inspection applications, from standard surface inspection methods MPI and DPI, to Manual and Advanced Ultrasonic tasks. Using a dedicated team of operatives under direct instruction and guidance from our Engineering team we not only add to the inspection quality but also make considerable cost savings by our direct management/control policy.

We provide Inspection solutions

- Conventional and Advanced Inspection Application Solutions.

To answer our client’s requirements, we provide novel conventional and advanced inspection methods, have significant experience in shutdown activities and applications, and take particular pride in our achievements and positive feedback from our clients with regard to our successes in the field.

We employ AUT applications; TOFD/Phased Array/Supplementary MUT typically on high pressure and sour service plant, including column and reactor vessel circ/seam weld inspections.

Tube inspection is well established and widely used in the Petrochemical Refinery, Chemical and Processing facilities, in the examination of tubing in system Heat Exchangers, Air Coolers, Feedwater Heaters and condensers. These key assets are common in the Oil and gas and Chemical industries and plant systems are reliant on these critical components, hence avoidance of failure is of high importance.

Eddy Current Tube inspection poses many challenges, due mainly to the wide variety of Exchanger types and configuration regarding to equipment design/tube type/geometry and tube materials. Consequently, the Eddy Current Tube test method has many application variables and correct test application selection is paramount. Test method(s) selection, probe/type/setting and the use of complementary methods will significantly influence defect detection and the test results and is of the upmost importance.

The inspection is used to detect typical tubing associated defects such as: pitting, corrosion, longitudinal and circumferential cracking, fretting, wall thinning and erosion at tube-support plates. Early detection of these defects can prevent failure and the determination of potential failure mechanisms, providing plant engineers not only with a tool to assess condition from a digitally recorded data set, but also facilitating the estimation of remaining life. The inspection results provide valuable data, from which to plan strategic plant operational and maintenance programs and ongoing unit monitoring.

The inspection is used to detect typical tubing associated defects such as: pitting, corrosion, longitudinal and circumferential cracking, fretting, wall thinning and erosion at tube-support plates. Early detection of these defects can prevent failure and the determination of potential failure mechanisms, providing plant engineers not only with a tool to assess condition from a digitally recorded data set, but also facilitating the estimation of remaining life. The inspection results provide valuable data, from which to plan strategic plant operational and maintenance programs and ongoing unit monitoring.

At Integrity NDT we have experienced personnel, using the latest technology for Eddy Current Tube inspection, with the following method/material type capability:

ECT – Conventional Eddy Current Inspection (Nonferrous metals)

PSEC – Partial Saturation Eddy Current Inspection (Ferrous Metals)

RFT – Remote Field Testing (Ferrous Metals and Heavy Wall Thickness)

NFT – Near Field Testing (Finned Tubes)

IRIS – Internal Rotary Ultrasonic Inspection*

*IRIS is an ultrasonic application; however, as it is used in tube inspection, it is shared here under Eddy Current section

Having secured long-term contracts to support continual refinery shutdown programs, our equipment and probe portfolio is wide ranging.

Integrity NDT also manufacture Eddy Current Tube Inspection Probes ‘in-house’, widening the inventory to suit each project work scope.

LPG SPHERICAL VESSEL INSPECTION

LPG SPHERICAL VESSEL INSPECTION

The common conventional industry practice of spherical vessel fabrication weldment is very time consuming, requiring the vessel to be taken out-of-service, its contents drained and the erection of internal and/or external access scaffolding to facilitate surface preparation and testing.

Offering significant ‘economies in time’ and many technical benefits, Integrity NDT provide Ultrasonic Time of Flight (TOFD) inspection of sphere vessel fabrication weldment, with the following benefits:

- The inspection can be conducted ‘on-line’ WITHOUT the need to remove the vessel from service

- Inspections are carried out from the external surface without the need for access scaffolding using highly experienced IRATA L3 & L2 certified ‘Rope Access Technicians’

- Inspection is carried out WITHOUT the need for the removal of surface coating

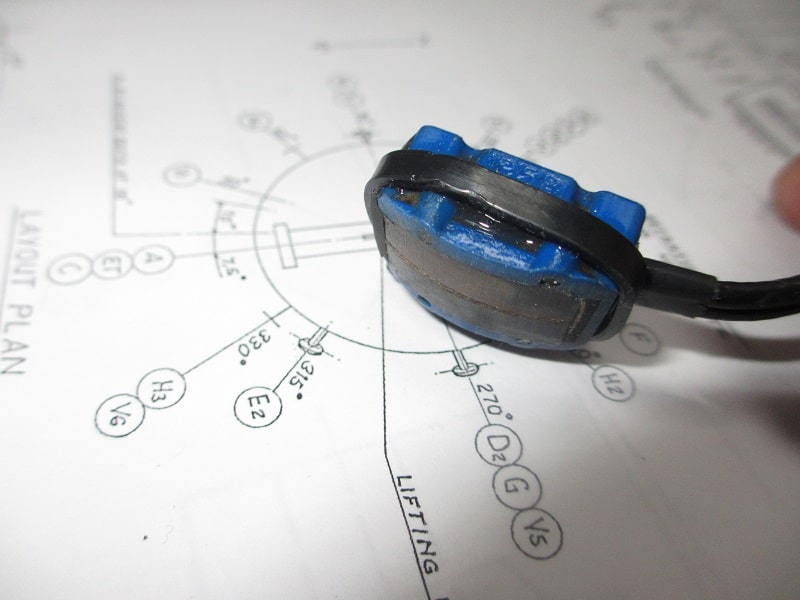

- Highly sensitive and rapid Ultrasonic TOFD inspection using specially designed Integrity NDT Magnetic Wheeled ‘I-Scanner’

- Precise defect sizing capabilities and repeatability ideal for defect monitoring

- High level of sensitivity to all defect flaw types

- Digitally recorded data with imaging

Ultrasonic Guided Wave Inspection

The effects of corrosion under insulation is a widespread

Phenomenon within the Petrochemical Refinery and Chemical Processing Sector, and screening for CUI by Ultrasonic Guided Waves is now an accepted practice.

The long-range inspection of pipelines has many advantages. From a single test location, the guided waves can be directed in opposing directions along the pipe length, testing up to several metres in length (dependant on the pipe dimensions/condition). This facilitates the of long pipe runs, including ‘insulated’ and ‘buried’ pipeline to screen for corrosion and cracking and corrosion-under-insulation (CUI). Inspections can be applied both off-line and operational systems (including ‘high temperature’).

For insulated pipes, only a local area of the pipe insulation is required to be removed , along with and loose surface debris, following which the ultrasonic transducer ring can be simply fitted to the pipe and is ‘ready-for-test’. The UGW works ‘dry-coupled’ and therefore no provision of couplant/water feed-system is required, as with standard ultrasonic applications

Following data analysis, UGW screening is backed by follow-up, localised supplementary inspections for confirmation.

With considerable experience and long-term client contracts supplying UGW inspection for Refinery system, refinery jetty and offsite systems, Integrity NDT are well placed to support your Engineering team and your UGW and CUI requirements.

The ultrasonic inspection of Austenitic welds presents many issues which need to be fully understood when developing an inspection strategy, and the inspection techniques must be developed specific to the parent and weld materials, and weld joint geometry.

Welds in Austenitic materials produce a large columnar grain structure which cannot be refined by heat treatment. This inhomogeneous weld structure results in anisotropic ultrasonic behaviour (opposed to welds in Ferritic materials which produce refined grains resulting in isotropic ultrasonic behaviour). This weld structure impacts on the ultrasound in many ways, resulting in:

- High levels of ultrasound attenuation

- Increased noise levels

- Ultrasonic beam scattering

- Ultrasonic beam bending

- Ultrasonic beam skewing

- Beam bending/skewing at the weld/parent interfaces

To best manage and overcome these many issues requires not only the use of specialist ultrasonic transducers (Focussed Transmit Receive Longitudinal wave TRL probes), but also a combination of different transducer types and ultrasonic test application methods needs careful consideration.

NDT Techniques for the inspection of Austenitic and dissimilar inspection are:

- Liquid Penetrant

- Focussed TRL Longitudinal Wave UT

- Standard Shear wave UT

- Phased Array UT

- TOFD UT

Using our experience in this field Integrity NDT can help to ensure safe operation of these critical plant components.